Operating a skid steer loader can be a game-changer on any construction or landscaping site. But do you really understand how much you can load without tipping over? In this guide, we’ll break down tipping load, lift capacity, and other vital specs to help you make the most of your skid steer while staying safe. Read on to become a skid steer pro!

Understanding Tipping Load in Skid Steers

What Is Tipping Load?

The tipping load is the maximum weight at which a skid steer will start to tip forward. It’s a crucial spec that tells you how much you can load into your machine without compromising stability. Exceeding this load can cause the skid steer to tip, leading to dangerous situations.

Why Tipping Load Matters

Knowing the tipping load helps you avoid accidents on the job site. It’s essential for:

- Safety: Prevents the skid steer from tipping forward.

- Efficiency: Ensures you’re operating within safe limits.

- Machine Longevity: Reduces strain on the skid steer’s components.

How Lift Capacity Relates to Tipping Load

Defining Lift Capacity

The lift capacity, often referred to as the Rated Operating Capacity (ROC), is typically 50% of the tipping load for wheeled skid steers and 35% for tracked models. This rating ensures a safety margin to avoid tipping.

Example:

- If a wheeled skid steer has a tipping load of 2,000 lbs, its ROC would be 1,000 lbs.

- For tracked skid steers, a tipping load of 2,000 lbs would result in an ROC of 700 lbs.

Importance of ROC

Operating within the ROC:

- Prevents Tipping Forward: Keeps the machine stable.

- Maintains Machine Performance: Avoids overloading the hydraulic system.

- Ensures Operator Safety: Protects the operator and those nearby.

Factors Affecting Skid Steer Tipping Load

Several factors can influence your skid steer’s tipping load:

- Machine Weight: Heavier machines have higher tipping loads.

- Wheelbase Length: Longer wheelbases increase stability.

- Attachment Weight: Heavy attachments, like buckets or pallet forks, reduce the tipping load.

- Terrain: Uneven or sloped ground can affect stability.

- Load Distribution: Uneven loads can cause tipping even within the ROC.

Calculating Your Skid Steer’s Lift Capacity

Step-by-Step Guide

- Find the Tipping Load: Refer to your skid steer’s spec sheet.

- Determine the ROC:

- Wheeled Skid Steer: ROC = Tipping Load × 50%

- Tracked Skid Steer: ROC = Tipping Load × 35%

- Account for Attachment Weight: Subtract the weight of any attachments.

- Consider Load Position: Lifting a load further away from the machine reduces stability.

Example Calculation

- Tipping Load: 3,000 lbs

- Attachment (Bucket): 500 lbs

- ROC: 1,500 lbs (wheeled skid steer)

- Effective Lift Capacity: 1,000 lbs (ROC – Attachment Weight)

How Attachments Affect Lift Capacity

The Impact of Buckets and Forks

Attachments like buckets and pallet forks add weight to the front of the skid steer, affecting the tipping load and ROC.

- Buckets: Used for carrying loose materials; their weight reduces lift capacity.

- Pallet Forks: Ideal for lifting pallets; lighter than buckets but still impact capacity.

Tips for Using Attachments

- Choose the Right Attachment: Use lighter attachments when possible.

- Position the Load Carefully: Keep heavy loads close to the machine.

- Regular Maintenance: Ensure attachments are in good condition to prevent unexpected failures.

Tips to Avoid Tipping Your Skid Steer

- Keep Loads Low: Carry loads close to the ground to maintain a low center of gravity.

- Distribute Weight Evenly: Uneven loads can cause tipping even within capacity limits.

- Avoid Sudden Movements: Accelerate and decelerate smoothly.

- Operate on Flat Ground: Slopes and uneven terrain increase the risk of tipping.

- Be Mindful of Lift Cycle: The top of the lift cycle is where tipping is most likely.

Understanding Skid Steer Specifications

Key Specs to Consider

- Tipping Load

- Rated Operating Capacity (ROC)

- Machine Weight

- Hydraulic Flow

- Lift Path (Vertical or Radial)

- Wheelbase and Track Width

Why Specs Matter

Manufacturers like Bobcat and John Deere provide detailed spec sheets. Understanding these helps you:

- Choose the Right Machine: Select a skid steer that meets your needs.

- Operate Safely: Know your machine’s limits.

- Plan Efficiently: Match machine capabilities to job requirements.

Vertical Lift vs. Radial Lift Skid Steers

Vertical Lift Machines

- Characteristics:

- Lift arms move straight up.

- Maintains load close to the machine.

- Advantages:

- Better reach at maximum lift height.

- Ideal for loading trucks.

- Considerations:

- Slightly heavier due to additional linkage.

Radial Lift Machines

- Characteristics:

- Lift arms move in an arc.

- Reaches further away at mid-height.

- Advantages:

- Better for digging and grading.

- Simpler design, potentially lower maintenance.

- Considerations:

- Less reach at full height.

Enhancing Lift Capacity Safely

Adding Counterweights

- Purpose: Balance the machine when lifting heavy loads.

- Benefits:

- Increases stability.

- Allows for maximum lift capacity without tipping.

Proper Maintenance

- Hydraulics: Regularly check for leaks and maintain fluid levels.

- Loader Arms: Inspect for wear and tear.

- Tires/Wheels: Ensure proper inflation and condition.

Operator Techniques

- Smooth Movements: Reduces dynamic forces that can cause tipping.

- Knowledge of Terrain: Adjust operations based on ground conditions.

- Awareness of Load Position: Keep loads close to the machine’s center.

Recognizing Signs of Overloading

- Rear Wheels Lifting: Indicates the load is too heavy.

- Hydraulic Strain: Slow or jerky movements of loader arms.

- Unusual Noises: Grinding or creaking sounds suggest stress on components.

- Warning Indicators: Modern machines may have alarms or lights.

Choosing the Right Skid Steer for Your Needs

Assessing Your Requirements

- Typical Load Weight: Choose a skid steer with an ROC higher than your heaviest load.

- Attachment Compatibility: Ensure the machine can handle the attachments you need.

- Job Types:

- Construction: May require higher lift capacity and vertical lift path.

- Landscaping: Might prioritize maneuverability and radial lift.

Comparing Manufacturers

- Bobcat:

- Known for reliability and durability.

- Offers a range of models with various specs.

- John Deere:

- Recognized for innovation and advanced features.

- Provides robust machines with high lift capacities.

Safety Tips for Operating at Maximum Capacity

- Conduct Pre-Operation Checks: Inspect the machine before use.

- Use Seatbelts and Safety Bars: Protects the operator during operation.

- Follow Manufacturer Guidelines: Adhere to specified limits and procedures.

- Stay Alert: Be aware of surroundings and potential hazards.

- Communicate: Use signals when working around others.

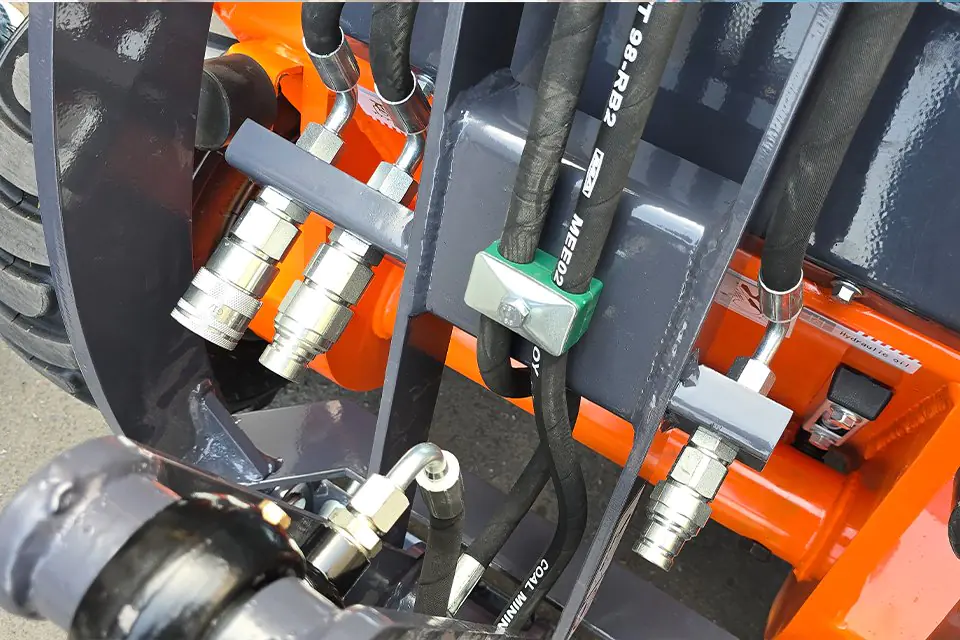

The Role of Hydraulics in Lift Capacity

Understanding Hydraulic Systems

- Function: Powers the loader arms and attachments.

- Components: Includes pumps, motors, hoses, and fluids.

Importance of Hydraulics

- Efficiency: Well-maintained hydraulics ensure smooth operation.

- Power: Affects the ability to lift loads quickly and safely.

- Maintenance:

- Regular Checks: Inspect for leaks and proper fluid levels.

- Filter Changes: Keep the system clean.

Common Mistakes to Avoid

- Ignoring Load Limits: Overloading can cause tipping and damage.

- Neglecting Maintenance: Leads to decreased performance and safety risks.

- Improper Attachment Use: Using the wrong attachment for a job can be dangerous.

- Operating on Uneven Ground: Increases the risk of tipping forward or sideways.

FAQs About Skid Steer Lift Capacity

Can I Increase My Skid Steer’s ROC?

Answer: No, the ROC is determined by the manufacturer’s design. Adding counterweights can help with stability but doesn’t change the ROC.

How Do Attachments Affect Tipping Load?

Answer: Attachments add weight to the front of the skid steer, reducing the load you can safely lift without tipping.

Is It Safe to Operate at Maximum ROC?

Answer: Yes, but with caution. Always ensure the load is balanced and operate on flat ground to avoid tipping.

Chinese Mini Skid Steer Loaders are versatile machines suitable for various tasks.

Quick Reference Glossary

- Load: The weight being lifted or carried.

- Tipping Load: The point at which the skid steer begins to tip forward.

- Lift Capacity/ROC: Maximum weight the machine can lift safely.

- Skid Steer: A compact, engine-powered machine with lift arms.

- Machine: Refers to the skid steer loader itself.

- Skid: The method of steering by skidding wheels on one side.

- Loader: The lift arm and attachment assembly.

- ROC: Rated Operating Capacity.

- Bucket: Attachment used for scooping and carrying materials.

- Fork: Attachment used for lifting pallets and similar loads.

- Hydraulic: System that uses fluid pressure to power movement.

- Attachment: Tools attached to the loader arms for various tasks.

- Vertical Lift: Lift arms that move straight up.

- Radial Lift: Lift arms that arc outwards.

Final Thoughts

Understanding the tipping load and lift capacity of your skid steer is essential for safe and efficient operation. By knowing your machine’s specifications and operating within those limits, you can maximize productivity while avoiding accidents.

Key Takeaways

- Know Your Machine: Always be aware of your skid steer’s tipping load and ROC.

- Use Attachments Wisely: Remember that attachments affect your load capacity.

- Operate Safely: Keep loads low and balanced; avoid sudden movements.

- Maintain Regularly: Proper maintenance ensures optimal performance.

- Stay Informed: Consult manufacturer specs and stay updated on best practices.

For further information and to explore a range of skid steers and attachments, check out our selection:

- Mini Skid Steer Loaders: Explore Models

- 1.2 Ton (2500 Lb) Mini Excavator: Learn More

- Remote Control Lawn Mower: Discover Innovation

It’s important to choose the right skid steer for your needs. Consider factors like tipping load, lift capacity, and attachments to make an informed decision. Remember, operating within your machine’s limits ensures safety and efficiency on every job.